Cabinet Box Construction

Our custom built boxes are made using our top of the line equipment to ensure that all sizes and measurements are accurate and consistent. We measure your project and manufacture to the 1/16 of an inch fit – specifically to your jobsite.

Typical interiors are in house tested ¾” fused melamine sides, shelves, and adjustable shelves with metal “L” brackets for fixing placement. On exteriors, we use in house tested conversion varnish and over 120 stock colors & stains to provide one of the best finishes available in high end cabinetry and furniture.

We build with quality to last a lifetime and if you ever have a problem with our products, we will help you maintain them for life – whether it be hardware adjustment, abuse and or damage repair, or just periodic touch up of natural wear & tear, contact us to schedule service.

We offer 3 different styles of construction; Faceless, Face framed, and Inset Face Framed. Here is a brief description of these options:

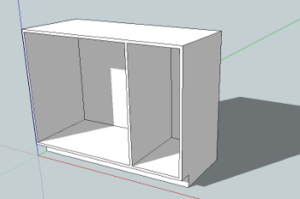

FACELESS

This cabinet is the most common in our industry, having a thin layer of PVC edge banding on the front, we have engineered our faceless box with blind dado construction giving a great deal more strength and stability – vastly superior to the more common butt joint construction used by the majority of our industry.

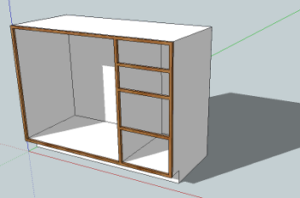

FACE FRAMED

This cabinet is very similar to the faceless box, but we add a solid ¾” wood frame to the front of the cabinet for added strength and stability. Both the face framed and faceless boxes will have “full overlay” doors and drawer fronts that only expose the box when the doors and drawers are open.

INSET FACE FRAMED

This cabinet is similar to the face framed box, but the face frame parts are slightly wider and the most distinguishing characteristic is that the doors are inset flush to the frame, thus leaving the face frame exposed for an early American feel in design.

In all cabinetry we produce, we incorporate the best lifetime warranted hinges and drawer guides available with soft close where available.